English

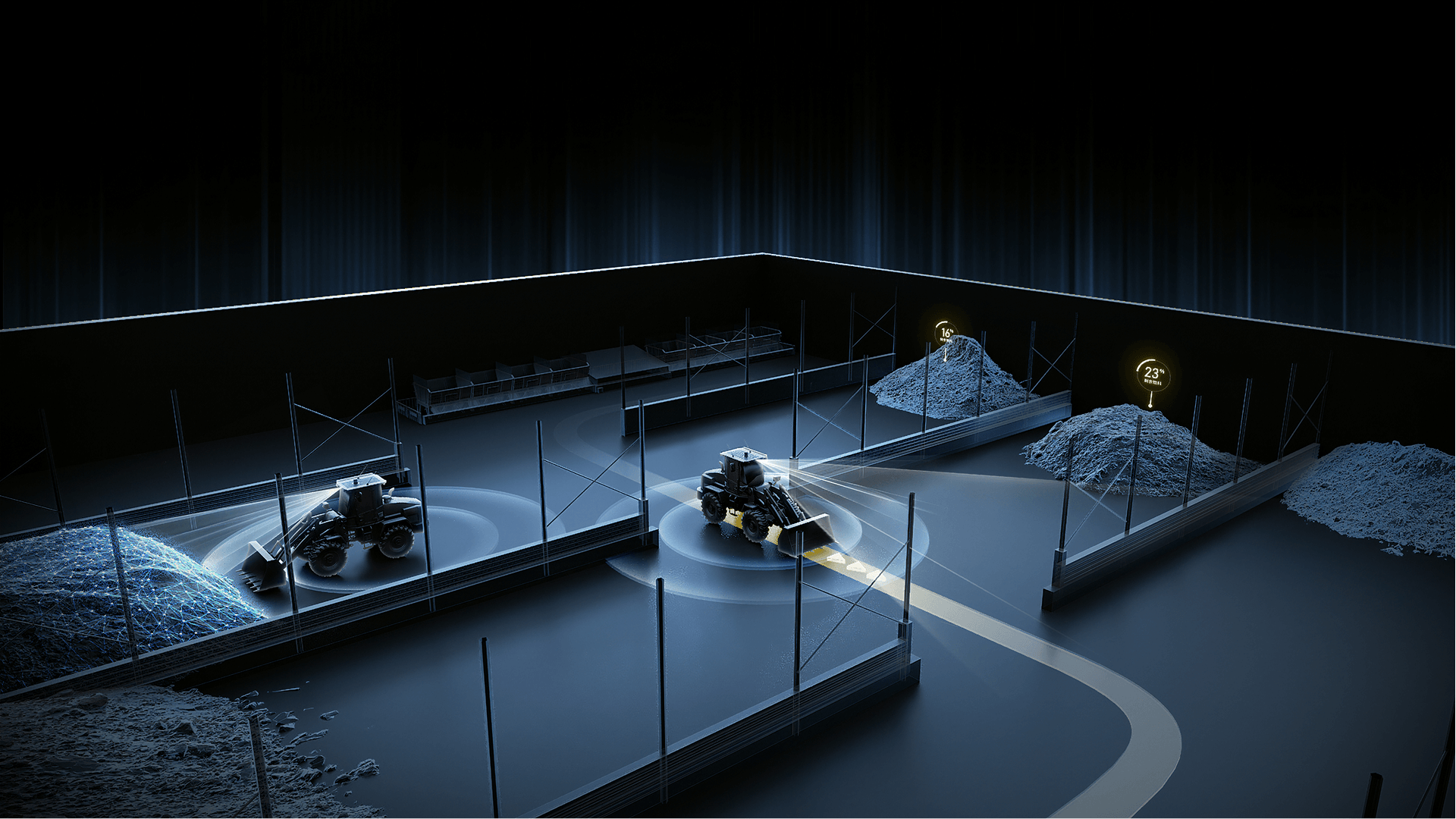

Unmanned Loading Robot

Powered by SmartEase's proprietary embodied AI, loaders can deliver uninterrupted 24/7 operations in industrial sites like batching plants, power facilities and chemical complexes. By integrating millimeter-level positioning, adaptive path planning and environment awareness, the system achieves complete unmanned work, significantly boosting efficiency while cutting labor costs.

Lingzai

The new paradigm of intelligent industry 24/7 continuous operation

Saved Operational Costs

30%

Reduced Energy Use

15%

Automation boosts efficiency by

120%

Maximum automation performance reaches

131%

Core Features

Dual-Side Smart Retrofitting

Loader Transformation

Batching Plant Transformation

Hardware Configuration

3D Laser

IMU & Angle Sensors

Front and Rear Cameras

Computing and Control Units

Millimeter-Wave Radar

Algorithm Configuration

Scene Perception Model

Motion Control System

Safety Protection System

loader.efficient

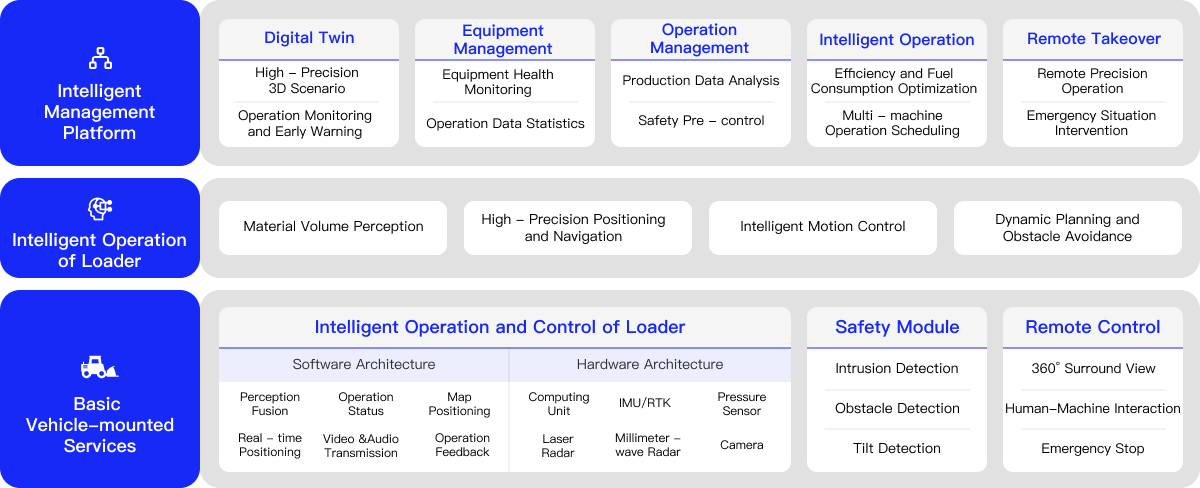

Solution Architecture

Product Capabilities

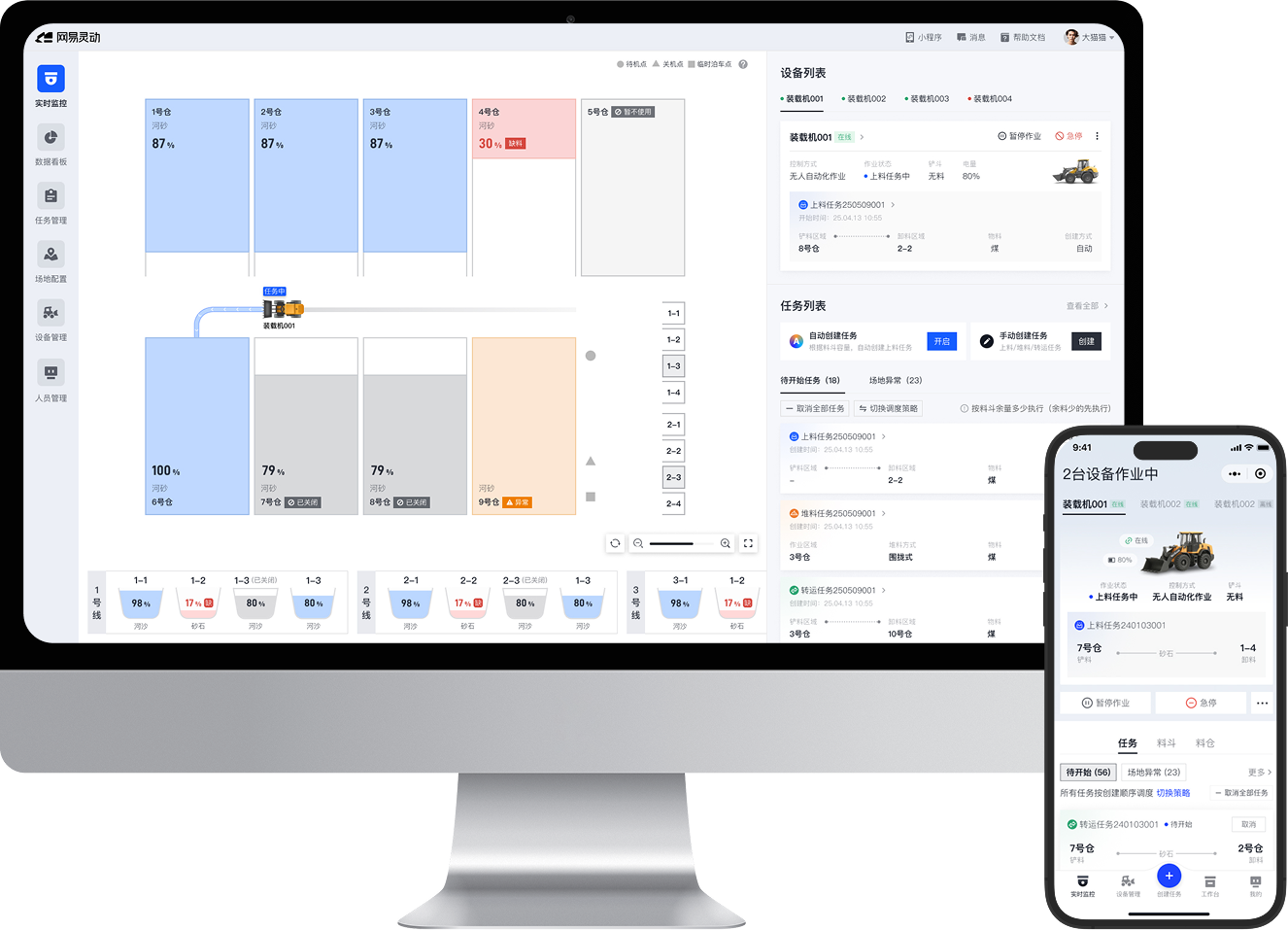

Dispatch Platform

Remote Control

Digital Twin

Map Deployment

Application Scenarios

Batching Plant

Fully autonomous loading, higher efficiency.

Chemical Plant

Unmanned operation in hazardous areas.

Power Plant

All-weather design ensures stable coal supply.

Port

Automated cabin clearing, efficient and smart.

Local Market Coal

24/7 auto loading, reducing labor and increasing capacity.

Slope Repair

Unmanned slope repair, precise and stable.

CONTACT US

Contact UsCollaboratively Shaping the Future of the Industry