English

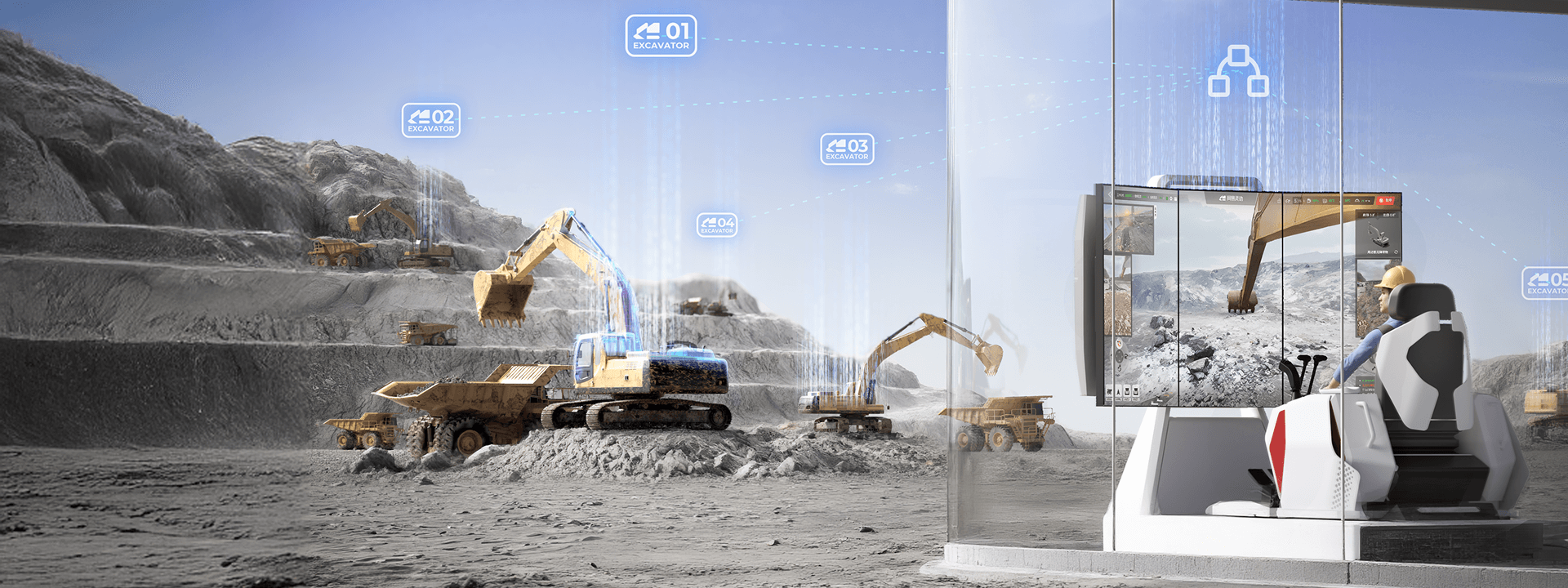

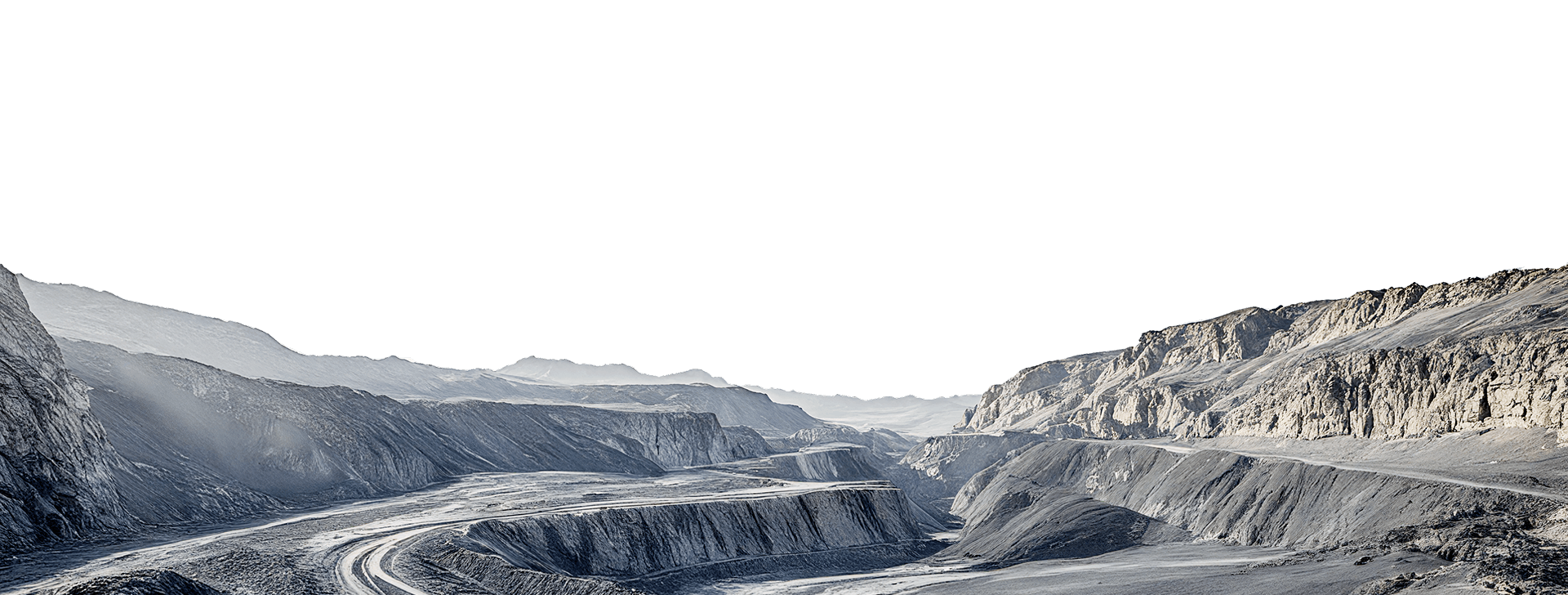

Open-Pit Mining Excavation Robot

SmartEase's excavator robots leverage proprietary industrial AI models, real-time connectivity, 3D digital twin technology, and high-precision positioning systems to enable remote collaboration and semi-autonomous operation, ensuring high efficiency and accuracy in complex construction environments.

Automated

Capabilities

Capabilities

Auto Loading

Auto Navigation

Auto Trenching

Auto Digging

Intelligent Transformation

Details

Backhoe

ISO/SAE

Simplified

Original

Angle Sensors

Pressure Sensor

Vision Perception Module

Control Center

Multi-Channel Solenoid Valves

Positioning & Navigation

Algorithm Configuration

Algorithm Configuration

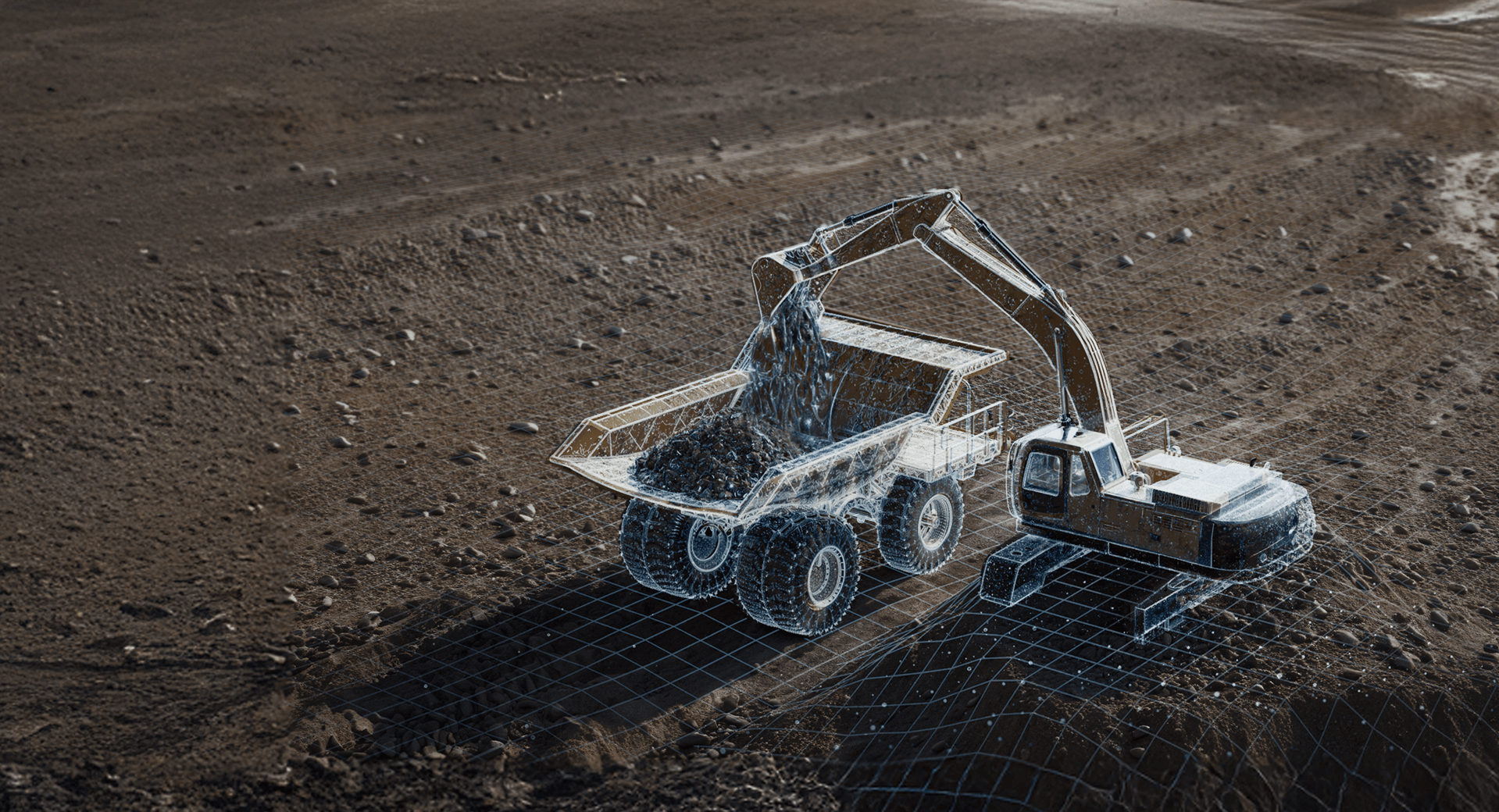

Creates precise 1:1 twin 3D models, continuously capturing real worker data to optimize smart operations.

Motion Control System

Creates hydraulic control models for centimeter-precision vehicle movement and detailed operation in complex environments.

Safety Guarantee

10m obstacle detection radius. -Real-time tilt monitoring. Remote/local manual override capability

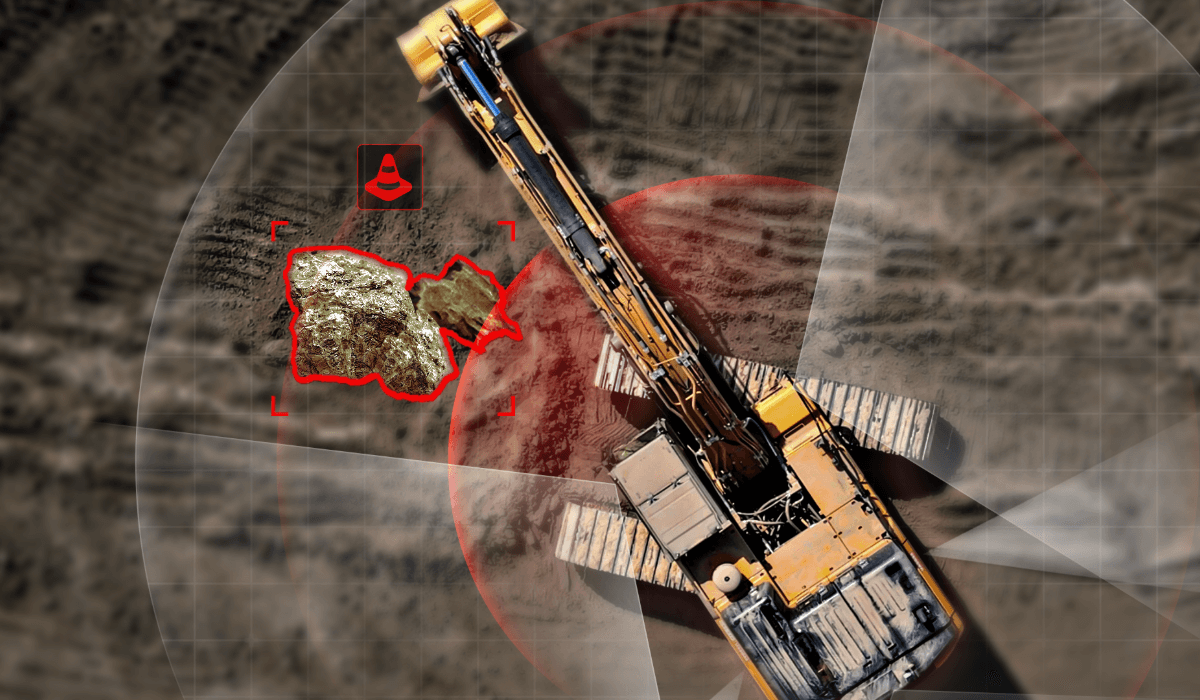

"Lingjue" Automatic Loading Model

The first embodied intelligence model for excavator loading in open-pit mines, using multimodal data-driven learning to solve traditional issues of adaptability and customization reliance.

Human-Level Efficiency per Device

80%

Autonomy Rate

70%

Multi-Machine "Shepherd" Control Mode

The system offers a progressive operational framework, ranging from remote control to semi-automated operations and advancing to a "shepherd mode" enabling one operator to manage multiple robots. It automates tasks like truck loading and path navigation, boosting efficiency and reducing manual work.

Staff efficiency ratio

240%

Industrial-Grade Digital Twin Environment

Smart protection for safety

Obstacle Detection

Pedestrian Detection

Tilt Detection

Continuously sense the surrounding environment and detect safe zones, providing timely feedback on collision risks.

Adaptive automation for varied scenarios

Basic Edition

Driver Client Software and Hardware

Onboard Software and Hardware

Basic Control

Simulated Cockpit

Simulated Cockpit Joystick/Mouse

Joystick/Mouse Emergency Stop

Emergency Stop HD Display

HD Display Fault Reporting

Fault Reporting Heartbeat Monitoring

Heartbeat MonitoringBasic Sensing

Obstacle Detection

Obstacle Detection 360° Surround View

360° Surround View Bucket Position

Bucket Position Overturn Warning

Overturn Warning Assisted View

Assisted View Excavator Posture

Excavator PostureAdvanced Edition

Driver Client Software and Hardware

Onboard Software and Hardware

AI Automation skills

Control Extension Pack

End Control

End Control Auto Digging

Auto Digging Slope Trimming

Slope Trimming Land Leveling

Land Leveling Auto Swing Loading

Auto Swing Loading Posture Logging

Posture LoggingPerception Extension Kit

AR Enhancement

AR Enhancement Spatial FOV

Spatial FOV Bucket Tooth Detection

Bucket Tooth Detection Live Twin Sync

Live Twin Sync Pedestrian Detection

Pedestrian Detection Dust Penetration

Dust PenetrationSmart Control Edition

Driver Client Software and Hardware

Onboard Software and Hardware

AI Automation Skills

Digital Twin Platform

Advanced AI Skills

Control Plus kit

Auto Truck Loading

Auto Truck Loading Auto Swing Loading

Auto Swing Loading Auto Navigation

Auto NavigationSensing Extension Kit

Scene Modeling

Scene Modeling Map Fusion

Map Fusion Supervision & Scheduling

Supervision & SchedulingMultiple Control Terminals

PC

Remote excavator control with just a computer. Supports keyboard/mouse, flight sticks, and gamepads. Stable operation over WiFi/5G

Cockpit

Ultra-HD display for immersive excavator operation.Compatible with multiple excavator models.Customizable physical controls

AR Glasses

3D overlay seamlessly integrated with real worksites. Intuitive interaction in a compact design.Adaptable for diverse wear scenarios.

Portable Terminal

Integrated joystick and touchscreen for quick control in complex environment

CONTACT US

Contact UsCollaboratively Shaping the Future of the Industry

Computer

Computer Cockpit

Cockpit AR Glass

AR Glass Portable end point

Portable end point